Due to the complexity and uniqueness of dental prosthesis parts and the resulting variety of tools and work steps, some of which are manual, there are still no approaches for assistance systems or automation solutions for the production of prosthetic implant structures in the production technology chain of a dental laboratory.

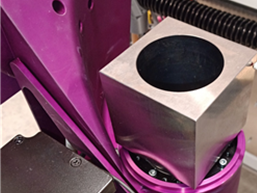

One focus of the project "Semi-automated modular manufacturing system for predominantly manual process chains; development of a semi-dry spark erosion, technological investigation of the results; development and provision of a camera-based assistance system for quality control; construction of a robot-based machine tool" is the development of an assistance system that collaborates with humans to provide support in monotonous and manual work steps, in the handling of workpieces of the CNC milling and spark erosion machine and in quality control. Another focus of the project is the spark erosion semi-dry machining and the machine technology required for this. And finally, the development of a new type of highly dynamic end effector prototype, based on solid-state joints made of fibre composites, should enable high-precision semi-dry spark-erosive machining.