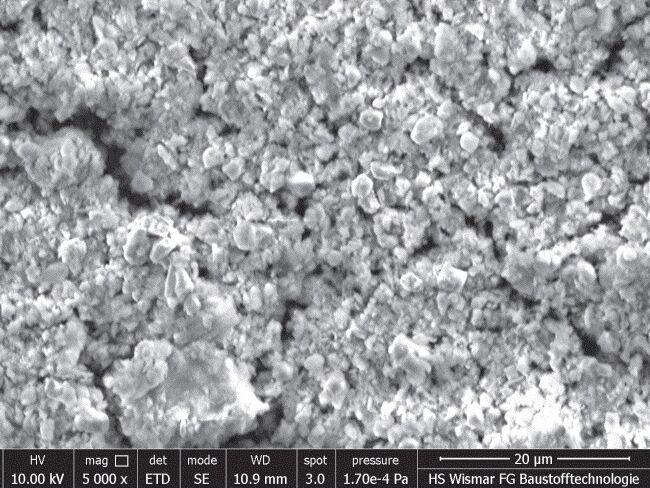

Every year in Germany alone, many millions of tonnes of mineral building materials are produced for recycling, which up to now have mainly been reused in low-value applications, e.g. As road substructure material. A special waste problem is posed by deconstructed asbestos cement products, which are currently disposed of exclusively in landfills under special conditions. The Department of Building Materials Technology / Building Physics devotes one of its main areas of applied research to the development of closed material cycles for cement-bound building materials. In the context of the project presented here as an example, the objective was the recovery of a hydraulic binder from asbestos cement products with the simultaneous complete destruction of the asbestos fibres, which have long been classified as hazardous to health. For this purpose, a combined thermal-mechanical treatment process on a low temperature/low energy level developed at the department is used, which completely converts the asbestos fibres into mineral particles that are harmless to health and the dominant cement stone portion of the asbestos cement into a hydraulic binder. A scanning electron microscope image gives an impression of the nature of the process product.

The end product has properties comparable to cement. For this purpose, the diagram in the picture documents the strength development of the hydraulic binder newly obtained from asbestos cement in comparison with standard cement. In view of its high water-binding capacity, it is particularly suitable for applications in civil engineering and in the field of soil improvement/soil consolidation. With the successful completion of this R+D project, a significant contribution is made to the solution of a pressing waste problem by showing recycling possibilities instead of landfilling. By documenting a practicable way to recycle mineral building materials, especially hydraulic binders, also makes a general contribution to the urgently needed sustainability and conservation of resources. The project was carried out in the modern laboratories of the Department of Civil Engineering, which offer state-of-the-art mechanical and physical testing facilities as well as equipment and methods of highly developed instrumental analysis.

Team: Department of Building Materials Technology / Building Physics

Staff Members: Dr. Julia von Werder, Yvonne Menzel, M.eng. Melanie Schomann, Andreas Haak